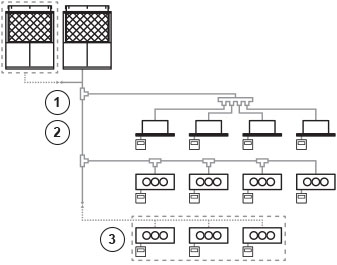

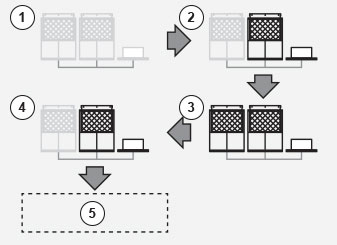

Load can easily be increased in the future by the addition of indoor and outdoor units without having to plumb pipe shafts. When specifying refrigerant pipe work, please choose the size according to the horsepower after the increase of units.

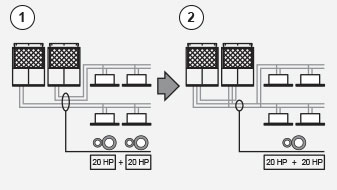

Example of a system. Added outdoor units. (Only for models with the same refrigerant.)

1. If there is a possibility for addition after setting up, please plan it so that the placement of a ball valve (sold separately) on a branch pipe on indoor/outdoor units is possible

2. Main pipe: Maximum gas pipe diameter 38,1 (1 1/2). Maximum fluid pipe diameter 19,05 (3/4)

3. Added indoor units. (Only for models with the same refrigerant.)

1. When 2 outdoor units are connected.

2. Capacity of indoor units connection is: Minimum 50% of the capacity of the smallest outdoor unit within the system. Maximum 130%: total capacity of the system outdoor units. Indoor units are same as multi series for buildings.

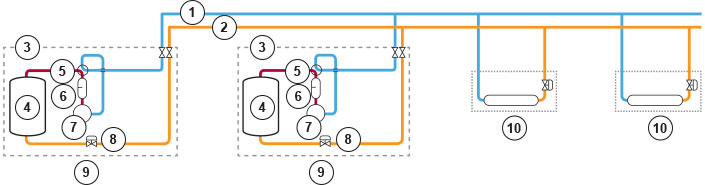

System diagram: 1. Gas pipe / 2. Fluid pipe / 3. 4 Direction valve / 4. Heat exchanger / 5. Oil separator / 6. Oil-surface sensor / 7. Compresor / 8. Electronic control valve / 9. Outdoor units / 10. Indoor units

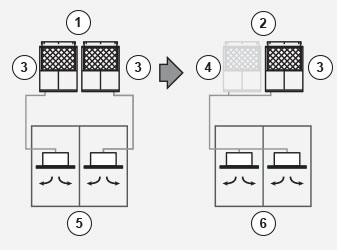

- Energy savings achieved by the Appropriate Capacity.

- Equational Program Function.

1. Up to this time / 2. W-Multi / 3. Load of around 10 HP (8 h operating) / 4. STOP / 5. Total operating hours: 16 hours / 6. Total operating hours: 8 hours

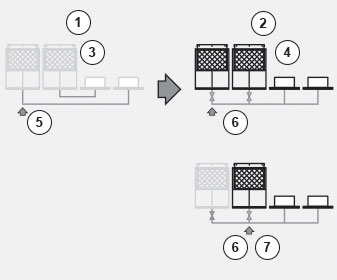

- System will not stop even during maintenance, due to Manual Backup Operating Function.

- Maintenance is possible during weekdays because it can continue operating during maintenance.

- Automatic Backup Operating Function enablescontinuous operation.

1. Up to this time / 2. W-Multi / 3. System stops during maintenance / 4. Continuous operation under the maintenance / 5. Machine in need of maintenance (maintenance during holidays) / 6. Machine in need of maintenance (maintenance during weekdays) / 7. Backup

- Renewal period prolonged due to rotation function.

Example of the rotation function: 1. Operating hours: 2.100 h (unit 1), 2.050 h (unit 2) / 2. System startup. Only unit 2 is operating / 3. Operating hours: 2.100 h (unit 1), 2.053 h (unit 2). Load increased. Units 1 and 2 are operating / 4. Operating hours: 2.105 h (unit 1), 2.058 h (unit 2). Load reduced. Only unit 2 is operating. / 5. Realization of averaging operating hours

- By using common header pipe work the installation cost and time is significantly reduced.

Example of a system with approximately 40 HP: 1. Up to this time / 2. W-Multi