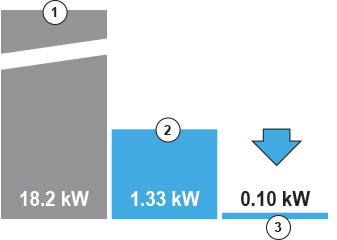

GHP with electrical generator. Only consumes 1% of the electricity required by Standard VRF systems!

Comparison of electrical consumption on a 71 kW outdoor unit: 1. Standard VRF for 73 kW / 2. ECO G for 71 kW / 3. ECO G High Power for 71 kW. Less than 1% of electrical consumption

Generates electricity during heating or cooling operation

Generates electricity and air conditioning (heating or cooling) at the same time by using remaining engine power. ECO G High Power can generate 2.0 kW electricity at a generation efficiency of more than 40%.

Generates up to 2 kW depending on air conditioning load.

Panasonic innovates again introducing a new GHP producing his own electricity

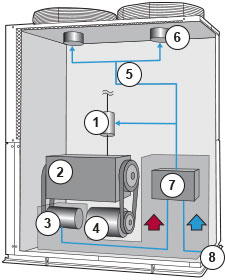

Equipped with a small generator of high-performance.

Compressor and generator are driven by gas engine. The generated electricity is used for the fan motor and cooling water pump of its own unit. The generating efficiency is more than 40%.

1. Cooling water pump / 2. Engine / 3. Generator / 4. Compressor / 5. Electricity flow / 6. Fan motor / 7. Electric control BOX (Inverter/Converter) / 8. Electric supply

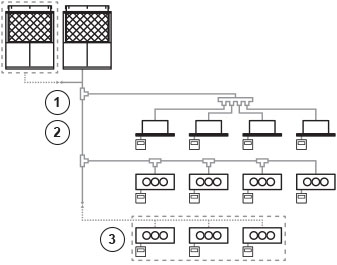

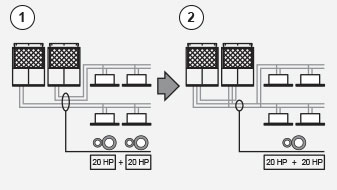

Load can easily be increased in the future by the addition of indoor and outdoor units without having to plumb pipe shafts. When specifying refrigerant pipe work, please choose the size according to the horsepower after the increase of units.

Example of a system. Added outdoor units. (Only for models with the same refrigerant.)

1. If there is a possibility for addition after setting up, please plan it so that the placement of a ball valve (sold separately) on a branch pipe on indoor/outdoor units is possible

2. Main pipe: Maximum gas pipe diameter 38,1 (1 1/2). Maximum fluid pipe diameter 19,05 (3/4)

3. Added indoor units. (Only for models with the same refrigerant.)

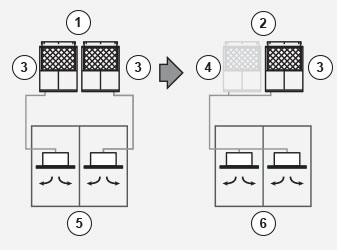

1. When 2 outdoor units are connected.

2. Capacity of indoor units connection is: Minimum 50% of the capacity of the smallest outdoor unit within the system. Maximum 130%: total capacity of the system outdoor units. Indoor units are same as multi series for buildings.

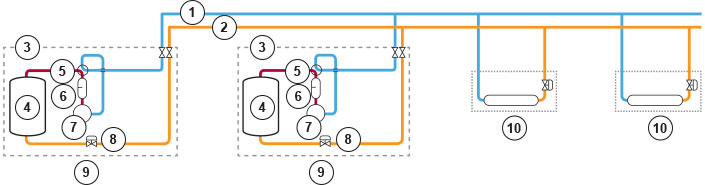

System diagram: 1. Gas pipe / 2. Fluid pipe / 3. 4 Direction valve / 4. Heat exchanger / 5. Oil separator / 6. Oil-surface sensor / 7. Compresor / 8. Electronic control valve / 9. Outdoor units / 10. Indoor units

- Energy savings achieved by the Appropriate Capacity.

- Equational Program Function.

1. Up to this time / 2. W-Multi / 3. Load of around 10 HP (8 h operating) / 4. STOP / 5. Total operating hours: 16 hours / 6. Total operating hours: 8 hours

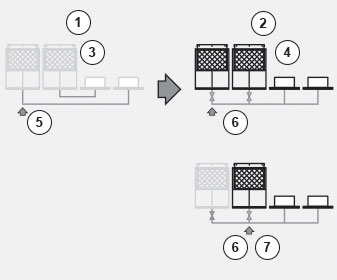

- System will not stop even during maintenance, due to Manual Backup Operating Function.

- Maintenance is possible during weekdays because it can continue operating during maintenance.

- Automatic Backup Operating Function enablescontinuous operation.

1. Up to this time / 2. W-Multi / 3. System stops during maintenance / 4. Continuous operation under the maintenance / 5. Machine in need of maintenance (maintenance during holidays) / 6. Machine in need of maintenance (maintenance during weekdays) / 7. Backup

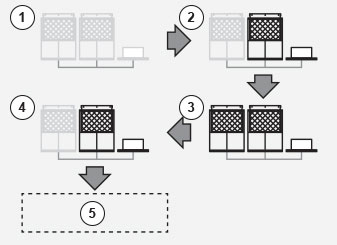

- Renewal period prolonged due to rotation function.

Example of the rotation function: 1. Operating hours: 2.100 h (unit 1), 2.050 h (unit 2) / 2. System startup. Only unit 2 is operating / 3. Operating hours: 2.100 h (unit 1), 2.053 h (unit 2). Load increased. Units 1 and 2 are operating / 4. Operating hours: 2.105 h (unit 1), 2.058 h (unit 2). Load reduced. Only unit 2 is operating. / 5. Realization of averaging operating hours

- By using common header pipe work the installation cost and time is significantly reduced.

Example of a system with approximately 40 HP: 1. Up to this time / 2. W-Multi

- System Advantage.

Capacity at cooling standard point (outlet temp 75ºC)

Outdoor unit: U-16GE2E5 15.00 kW / U-20GE2E5 20.00 kW / U-25GE2E5 30.00 kW / U-30GE2E5 30.00 kW. Hot water piping allowable pressure 0.7 MPa. Hot water circulation rate 3.9 m³/h. Hot water tube size Rp 3/4

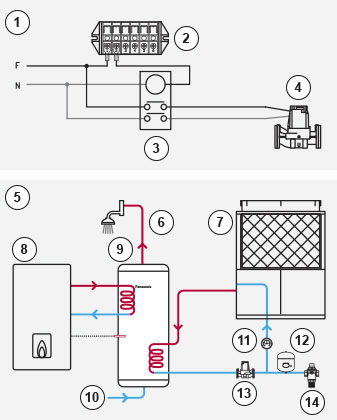

- All the items illustrated in this drawing (except the outdoor unit) are not supplied by Panasonic.

- During start up, set temperature value of the water in the outdoor unit's parameter.