Warum umrüsten?

It is often said that legislation is ruling our lives but sometimes it is there to help save lives. R22 phase out can be described as one of these and from Jan 1st 2010 the use of Virgin (new) R22 refrigerant was banned within the European Union.

Panasonic are doing our part

We aWe at Panasonic are also doing our part – recognising that all finances are under pressure at the moment. Panasonic has developed a clean and cost effective solution to enable this latest legislation to offer less financial impact on your business as much as possible.

By bringing a simple solution to the problem Panasonic can renew all Split Systems and PACi systems; and depending upon certain restrictions we don’t even limit the manufacturer’s equipment we are replacing.

By installing a new high efficiency Panasonic R410A system you can benefit from around 30% running cost saving compared to the R22 system. The installation can also qualify for the government’s ECA (Enhanced Capital Allowance Scheme) which enables you to offset the cost against your Capital Gains Tax.

1. Check the capacity of the system you wish to replace

2. Select from the Panasonic range the best system to replace it with

3. Follow the procedure detailed in the brochure and technical data Simple...

Notes on Reuse of Existing Refrigerant Piping

It is possible for each series of PE1 type and PEY1 type outdoor unit to reuse the existing refrigerant piping without cleaning when obtained a certain condition. Make sure that the requirements under the section “Notes on Reuse of Existing Refrigerant Piping”, “Measurement Procedure for Renewal” and “Refrigerant Piping Size and Allowable Piping Length” will be satisfied in order to carry out . Also, check the items with regard to section “Safety” and “Cleaning”.

1. Prerequisite

- If the refrigerant used for the existing unit is other than R22, R407C and R410A, the existing refrigerant piping cannot be used.

- If the existing unit has another use than air conditioning, then existing refrigerant piping cannot be used.

- If there is a hollow, crack or corrosion on the piping, make sure to install new piping.

- If the existing piping is other than capable of reuse of piping as shown in the flowchart, make sure to install new piping.

- In case of multiple operation type, use our genuine branch piping for refrigerant R410A.

3. Cleaning

- When the refrigerant oil used for the existing unit is other than the listed below, make sure to install new piping or wash it thoroughly before reusing it.

[Mineral Oil] SUNISO, FIORE S, MS

[Synthesized oil] alkyl benzene oil (HAB, parallel freeze), ester oil, ether oil (PVE only)

- If the existing pipes in the outdoor and indoor units remain disconnected, make sure to install a new piping or wash it thoroughly before reusing it.

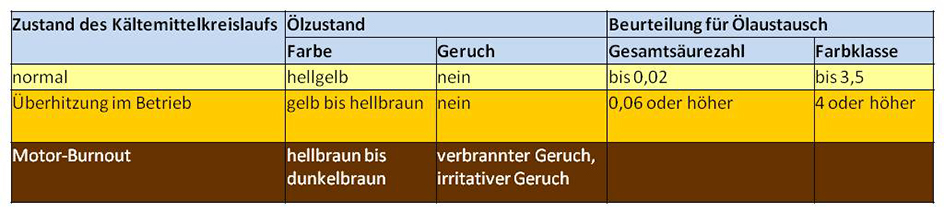

- If the discolored oil or residue remains in the existing piping, make sure to install a new piping or wash it thoroughly before reusing it. See “Deterioration Criteria for Refrigerant Oil” in table 3.

- If the compressor of the existing air conditioner has a failure history, make sure to install a new piping or wash it through thoroughly before reusing it.

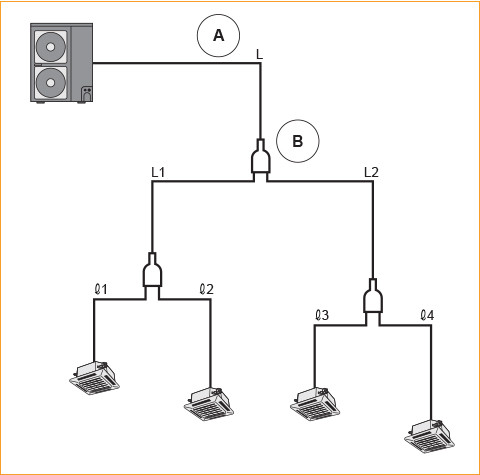

Abweichende Rohrleitungsdurchmesser sind nur für den Hauptstrang L zulässig. Falls die Leitungsgröße der Abzweigstränge L1, L2 und ℓ1 bis ℓ4 abweicht, müssen dort neue Rohrleitungen mit Standard-Durchmesser installiert werden. Dabei dürfen nur die speziell für R410A vorgesehenen Abzweige von Panasonic verwendet werden.

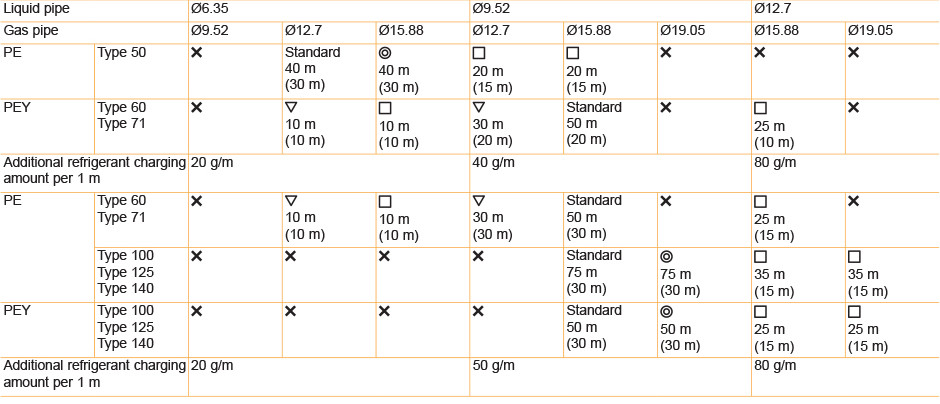

It is not necessary to charge with additional refrigerant until the charge less pipe length in the table 2.

If the pipe length is exceeding the charge less pipe length, charge with additional refrigerant amount per 1 m according to the equivalent length.

2. In case of simultaneous operation of multiple units

Calculate the refrigerant charging amount according to the calculating method of the standard piping diameter.

As to the additional refrigerant charging amount per 1 m, refer to the additional amount in the table 2.

Notes on Renewal for Simultaneous Operation of Multiple Units

Capacity class (Standard piping size):

- Type 50: Ø6.35 Liquid pipe / Ø12.7 Gas pipe

- Type from 60 to 140: Ø9.52 Liquid pipe / Ø15.88 Gas pipe

- Type 200: Ø9.52 Liquid pipe / Ø25.4 Gas pipe

- Type 250: Ø12.7 Liquid pipe / Ø25.4 Gas pipe

A: Main pipe

B: Branch pipe

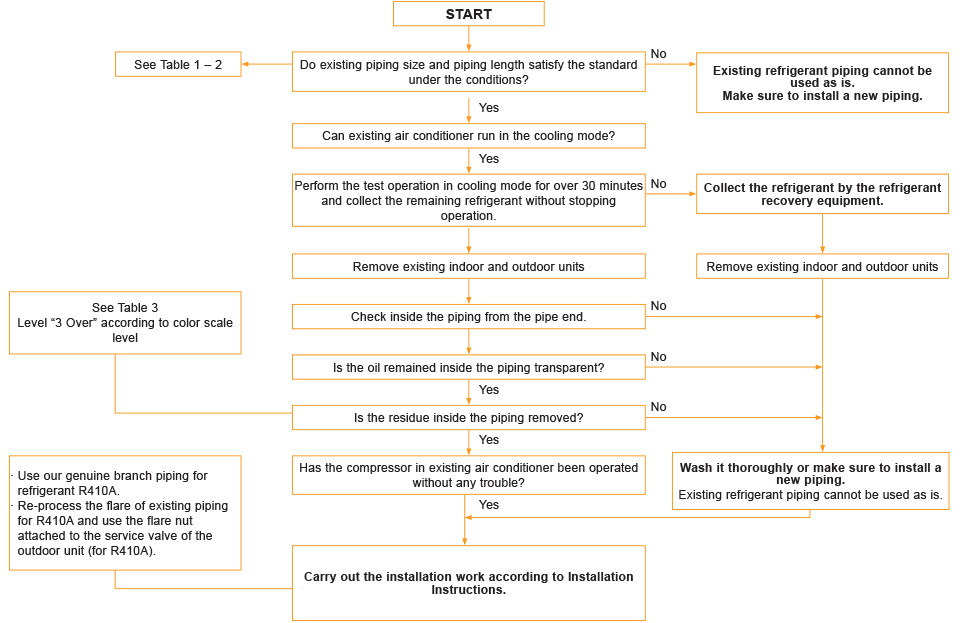

Observe the following procedure when reusing the existing piping or carrying out renewal installation work. Flowchart of Existing Piping Measures Criteria for PE1 Type and PEY1 Type Outdoor Unit

Opposite side dimension of flare nut (mm)

Piping size: Ø6.35. For R410A: 22. For R22/R407C: 22.

Piping size: Ø9.52. For R410A: 22. For R22/R407C: 22.

Piping size: Ø12.7. For R410A: 26. For R22/R407C: 24.

Piping size: Ø15.88. For R410A: 29. For R22/R407C: 27.

Piping size: Ø19.05. For R410A: 36. For R22/R407C: 36.

Check if reuse of existing refrigerant piping is possible based on the following chart. The standards other than this one (difference of elevation, etc.) are identical to the requirements of ordinary refrigerant piping.

Table 2 - 1 Refrigerant piping size: 3.6 - 14.0 kW type (mm)

In case of type 71, standard size is liquid pipe Ø9.52 / gas pipe Ø15.88.

There is a limitation to liquid pipe Ø9.52 / gas pipe Ø12.7and to liquid pipe Ø12.7 / gas pipe Ø15.88.

However, they are applicable for different diameter’s pipes.

Table 2 - 2 Refrigerant piping size: 20.0 - 25.0 kW type (mm)