100 % Panasonic, the DNA of Japanese craftsmanship

Applying advanced technologies that truly make life better, we live by an unparalleled commitment to product quality.

Panasonic is building on the Japanese tradition of uncompromising quality control worldwide, developing and manufacturing fine products and delivering them to customers everywhere.

At Panasonic, we believe that the best air conditioner is one that works quietly and effectively in the background whilst minimising its impact on the environment

People who use our products can look forward to long years of high-quality performance without the need for constant service. As part of our rigorous design and development process, Panasonic air conditioners undergo a variety of stringent tests to ensure their effectiveness and long-term reliability. Tests for durability, waterproofing, shock resistance, and noise are conducted on component parts or on the finished products themselves.

As a result of all of these time consuming efforts, Panasonic air conditioners meet industrial standards and regulations in every country where they are sold.

International Standard Quality

To uphold the company’s reputation around the world, Panasonic strives continuously to offer quality with minimized environmental impact.

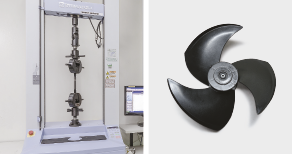

Reliable parts that meet or exceed

industrial standards.

In every country where they are sold, Panasonic air conditioners comply with all required industrial standards and regulations. In addition, Panasonic conducts stringent testing to ensure the reliability of parts and materials. The strength of the resin material used in a propeller fan is confirmed by a tension test.

Compliance with RoHS /

REACH substance restrictions.

Panasonic products and used materials strictly comply with chemical substance restrictions as defined by RoHS or REACH. During the development and production of parts, stringent inspections are conducted on over 100 materials to ensure that no hazardous substances are included.

Sophisticated production process.

Panasonic’s air conditioner production lines employ state-of-the-art factory automation technologies to ensure products are manufactured with high attention to quality to meet expectations of reliability and trustworthiness.

Durability

At Panasonic we know the importance of a long service life with minimal maintenance. That’s why we subject our air conditioners to a wide range of stringent durability tests.

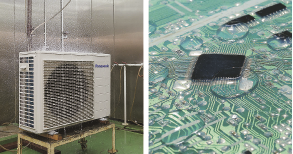

Long-term durability test.

To ensure durability and stable operation for many years, we conduct a long-term continuous operation test under conditions that are much more severe than actual operating conditions.

Compressor reliability test.

After the continuous operation test, we remove the compressor from a selected outdoor unit, disassemble it, and examine the internal mechanisms and parts for potential failure. This helps ensure reliable long-term performance under harsh conditions.

Waterproofing test.

The unit - which is subject to rain and wind - complies with IPX4 waterproof specifications. Contact sections on printed circuit boards are resin-potted to prevent adverse effects caused by exposure to water (an unlikely occurrence).