Introduction

CO₂ (R744), as a natural refrigerant, is increasingly applied in refrigeration systems. The market transition from high-GWP refrigerants to eco-friendly solutions goes hand in hand with technological developments like CO₂ transcritical inverter units. To meet the growing interest in natural refrigerants technology, the refrigeration market members need awareness-raising, training, and reliable knowledge.

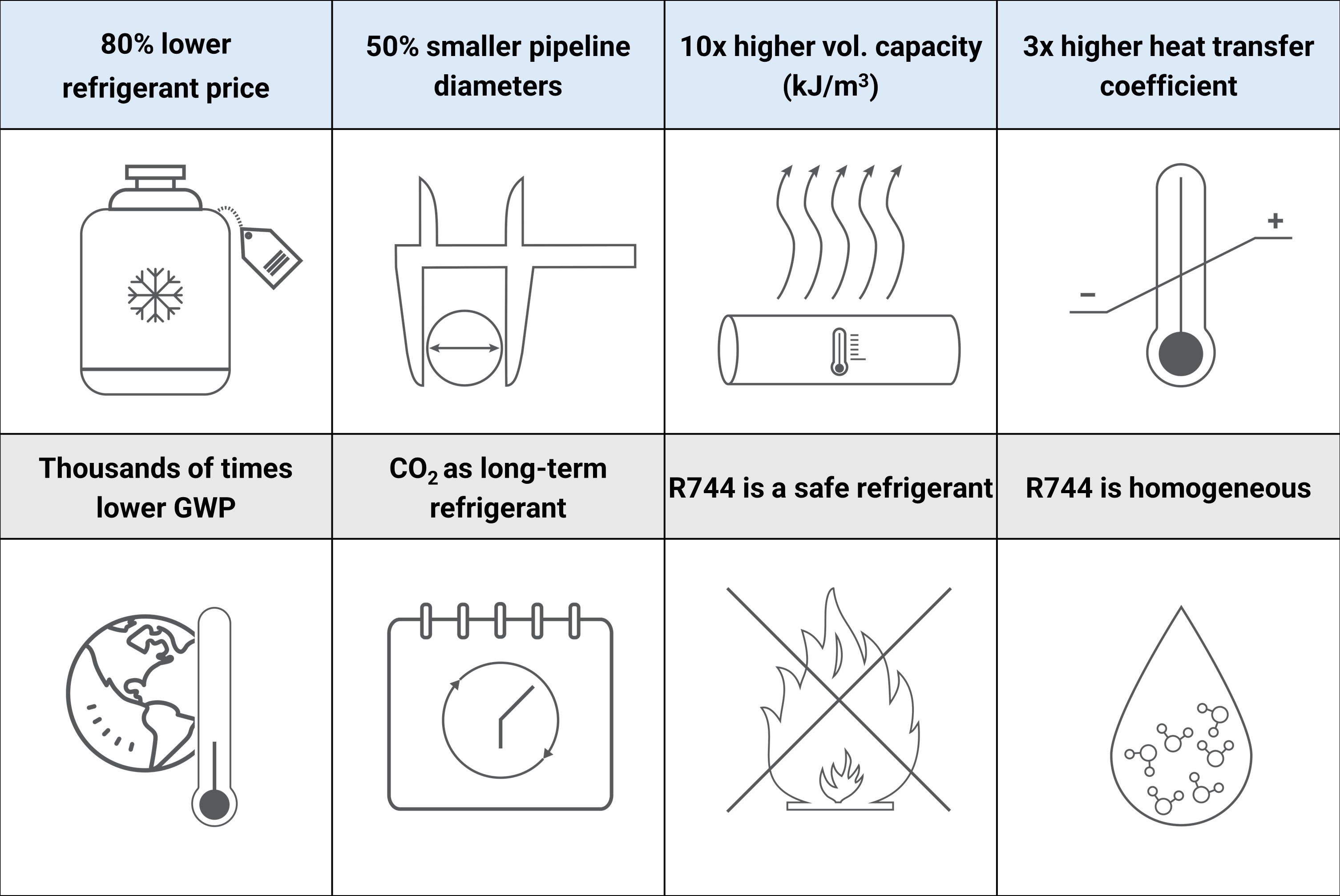

In the following material, we have compiled the main reasons why you should consider R744 refrigerant. Discover 5 compelling arguments to consider switching from standard HFCs to natural and eco-friendly CO2 refrigerant.

Reason 1: F-gas Regulation restrictions

European F-GAS Regulation No. 517/2014 to reduce the use of HFCs by 79% by 2030

The previous European Regulation No. 517/2014 (F-gas Regulation) aimed to reduce the use of harmful HFCs by 79% by 2030 [1]. The law is successively and gradually phasing out the HFC refrigerants, moving towards more eco-friendly solutions. The new F-gas Regulation (EU) 2024/573 was adopted on 7 February 2024, and started to apply on 11 March 2024 [more info].

Refrigerants with GWP > 2500 have been banned since 2020

From January 2020, prohibition is applied to “Stationary refrigeration equipment, that contains, or whose functioning relies upon HFCs with GWP of 2500 or more, except equipment intended for application designed to cool products to temperatures below -50 °C” [2], so for example R404A (GWP = 3922) or R507A (GWP = 3985) in such equipment may not be used.

Ban on use of refrigerants with GWP > 150 since 2022

At the beginning of 2022, further bans were introduced – it is now prohibited for “Refrigerators and freezers for commercial use (hermetically sealed equipment) that contain HFCs with GWP of 150 or more” [2].

Additional and current restrictions are applied to “Multipack centralized refrigeration systems for commercial use with a rated capacity of 40 kW or more that contain, or whose functioning relies upon fluorinated greenhouse gases with GWP of 150 or more, except in the primary refrigerant circuit of cascade systems where fluorinated greenhouse gases with a GWP of less than 1 500 may be used” [2].

5th of April 2022 – a proposal to update the current F-gas Regulation with more restrictions on HFCs

Moreover, on the 5th of April 2022, the European Commission made a legislative proposal to update the current F-gas regulation. The amendment establishes a more accelerated phase-down schedule for hydrofluorocarbons and a significant reduction in the use of HFC refrigerants in the coming years.

Currently (August 2023), the European Commission, the co-legislators in the European Parliament, and the Council of Ministers are negotiating the proposal [3].

Each side has already presented its initial position on the issue [4], and the European Parliament’s proposal is the most restrictive. It is clear that if the proposal is adopted, there will be a complete phase-out of HFCs and mixtures, and only natural refrigerants, such as CO₂ (R744), can be used for most applications.

7th of February 2024 - complete phase-out of HFCs consumption before 2050

The consumption of hydrofluorocarbons (HFCs) will be completely phased out by 2050, and the production of HFCs, in terms of production rights allocated by the Commission, will be phased down to a minimum (15%) as of 2036 [more here].

The law’s update accelerates the timetable for phasing out HFC refrigerants and significantly reduces their use in the upcoming years. According to the regulation, the quota of HFC refrigerants will be completely banned by 2050.

New restrictions were also presented on stationary refrigeration, specifically: “Refrigeration equipment, except chillers and equipment covered in points (4) and (6), that contains, or whose functioning relies upon: fluorinated greenhouse gases with a GWP of 150 or more, except if required to meet safety requirements at the site of operation [page 54 in the source]”. The ban will take effect on January 1, 2030.

Reason 2: Advantages of CO2 over HFCs

Several R744 myths require clarifying. Despite many claims that law restrictions forcing sustainable solutions are the only serious reason for switching to CO₂, this natural substance is characterized by several unique thermodynamical and functional features, allowing energy-efficient cooling and significantly benefiting its users and final customers.

80% lower refrigerant price

Due to the EU F-gas regulation (including the quota system under Regulation 2024/573), prices of high-GWP HFC refrigerants in Europe have risen significantly in recent years, and many market observers expect continued upward pressure on those prices.

While CO₂ (R744) remains comparatively inexpensive, a more conservative estimate is that CO₂ can cost several times less per kilogram than typical HFCs (often in the range of 2–5× lower, depending on the specific HFC, purity, supply chain margins, and regional factors).

50% smaller pipeline diameters

The physical and thermodynamical properties of R744 refrigerant allow the use of pipelines with significantly smaller diameters than HFCs. For a given refrigeration installation, the diameter of the suction line for R744 can be up to 2.5 times smaller than for a commonly used HFC refrigerant installation. Moreover, due to the high density of R744, compressors in CO2 systems are more compact than those used in HFCs. In CO₂-based systems powered by iCORE series units, the pipeline length can range from 25 up to even 100 meters (one way). At such distances, the investment cost can be significantly reduced, since pipelines in CO₂ installations can be up to two times smaller compared to HFC systems.

10x higher volumetric cooling capacity (kJ/m3)

The volumetric cooling capacity of R744 is significantly higher than conventional HFC/HFO refrigerants. It reaches around 22 500 kJ/m³ (at 0 °C), while for R449A it is approximately 5 400 kJ/m³, and for R454C about 3 800 kJ/m³ at the same temperature. Generally, the volumetric cooling capacity of R744 is still around 4–6 times higher than for these lower-GWP HFC/HFO refrigerants.

3x higher heat transfer coefficient

A high heat transfer coefficient characterizes R744. At the same saturation pressure, its value is about 3 times higher than with HFCs [6, 7]. As a result, heat exchangers such as condensers, evaporators, or internal plate heat exchangers do not require a large heat transfer area. Thus, these components can be compact and operate at a lower temperature differences.

Thousands of times lower GWP

What distinguishes CO₂ most among HFCs is its GWP value, which equals 1. In comparison, the GWP of R448A refrigerant is 1386; for R404A, the GWP has a value of 3922. It means that by releasing 1 kg of R404A into the atmosphere, we contribute 3922 times more to the greenhouse effect than by releasing 1 kg of R744 refrigerant.

CO2 as a long-term refrigerant

Currently, there are no regulations governing the use of R744, either reducing or phasing out carbon dioxide, so it can be viewed as a long-term and future-proof refrigerant with significant value in reducing the carbon footprint of companies.

CO₂, as a natural refrigerant, is seen as one of the best refrigerants after the planned update of the F-gas regulation.

R744 is a safe refrigerant

It is non-toxic (in low concentrations) and non-flammable. These properties make R744 a safe refrigerant and ensure easy refrigeration system servicing. This refrigerant is classified in safety group A1. It is chemically inert and thus not corrosive to copper or brass. CO₂ is compatible with many materials and has good miscibility with compressor lubricants.

Finally, in the supercritical state, it has unique solvent properties [8], such as low viscosity and high diffusivity, which affects the cleanliness of the installation on the high-pressure side.

R744 is a homogeneous refrigerant

CO₂, as a natural refrigerant, is a simple, single-molecule compound. Thanks to this, there is no temperature glide/pressure drop during subcritical operation. The system charging is also simplified, as R744 can be charged into the installation in gaseous form without the stratification problems that occur with zeotropic HFC refrigerants (400 family) due to the different boiling points of the components. By contrast, to recharge HFC systems, the entire installation must be discharged and refilled, since HFC is a non-homogeneous refrigerant. In addition, the glide imposes limitations on HFC (and A2L) refrigerants in low-temperature applications, making it difficult to reach below -40 °C. These features of the CO₂ refrigerant result not only in its user-friendliness, availability, and long-term use but, thanks to its efficiency, may bring significant cost savings and improved quality of the final product.

Reason 3: High potential for heat recovery

The discharge temperature for R744 quickly reaches over 100°C. It brings excellent potential for heat reclaim in retail systems, which can be used for central heating or obtaining domestic hot water.

The heat recovery system can reduce the overall energy costs as an optional function of the primary cooling operation. It also increases the efficiency of a system at high ambient temperatures. Nowadays, it has become standard in European supermarkets. It should be used everywhere when possible.

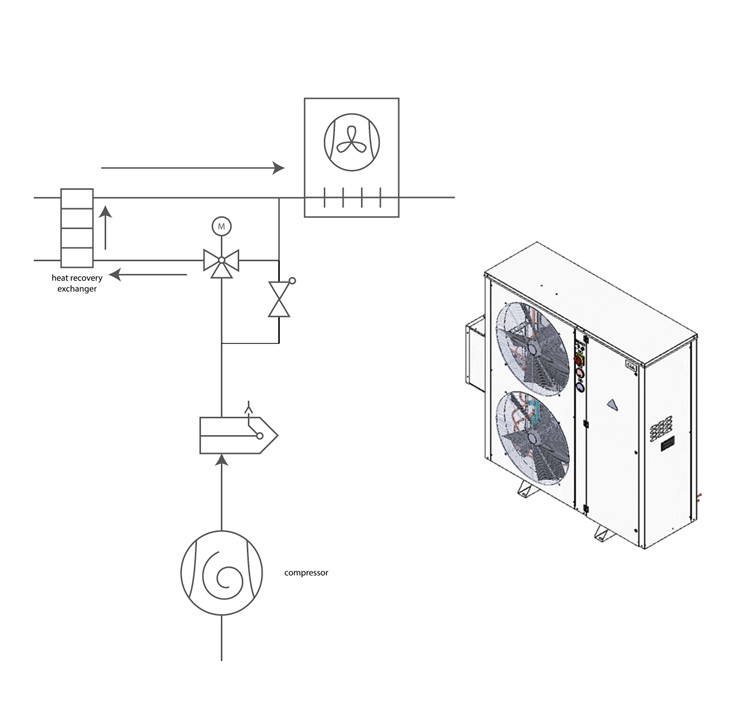

The heat recovery option in the selected iCORE OCU/SCU-CRC Series units is a complex, controller-managed system integrated into the unit, with safety features and an optimally sized plate heat exchanger.

Example of the heat recovery circuit for OCU-CRC150A08

Reason 4: Cost savings

Refrigeration systems operating with CO₂ transcritical inverter units offer great potential for savings. Thanks to the energy-efficient inverter technology, advanced control automation, and high efficiency of the transcritical unit, the total annual operating costs can be about 20% lower compared to a standard HFC refrigeration system [9, 10]. With the heat recovery option, it could even be lower.

There are installations where it has been confirmed that by changing the system from R507A and R404A to CO₂, energy consumption has been reduced by 30% compared to the last five years with the old system [11].

The actual kWh/year energy consumption is mainly reduced by the possibility of fluid refrigeration capacity modulation in a wide range, optimized temperature regulation, decreased quantity of defrost cycles, and the elimination of the costs associated with the conventional fuels consumed by the heating system (when the heat reclaim is used).

The total investment cost of a CO₂ refrigeration system may be higher, but with proper configuration of the system based on transcritical inverter units, thanks to the increased efficiency and lower operating cost, the return on investment time for this additional cost over an HFC system can be very reasonable.

Reason 5: Proven CO2 technologies

CO₂ refrigeration technology has already reached a highly advanced level, and it continues to evolve dynamically. Today, more and more transcritical CO₂ systems equipped with state-of-the-art automation are available on the market, proving their efficiency even in applications with high capacity demands. A wide range of dedicated components designed specifically for CO₂ - such as evaporators, expansion valves, pipes, liquid receivers, and precision instrumentation - ensures compliance with the highest standards of strength, safety, and reliability.

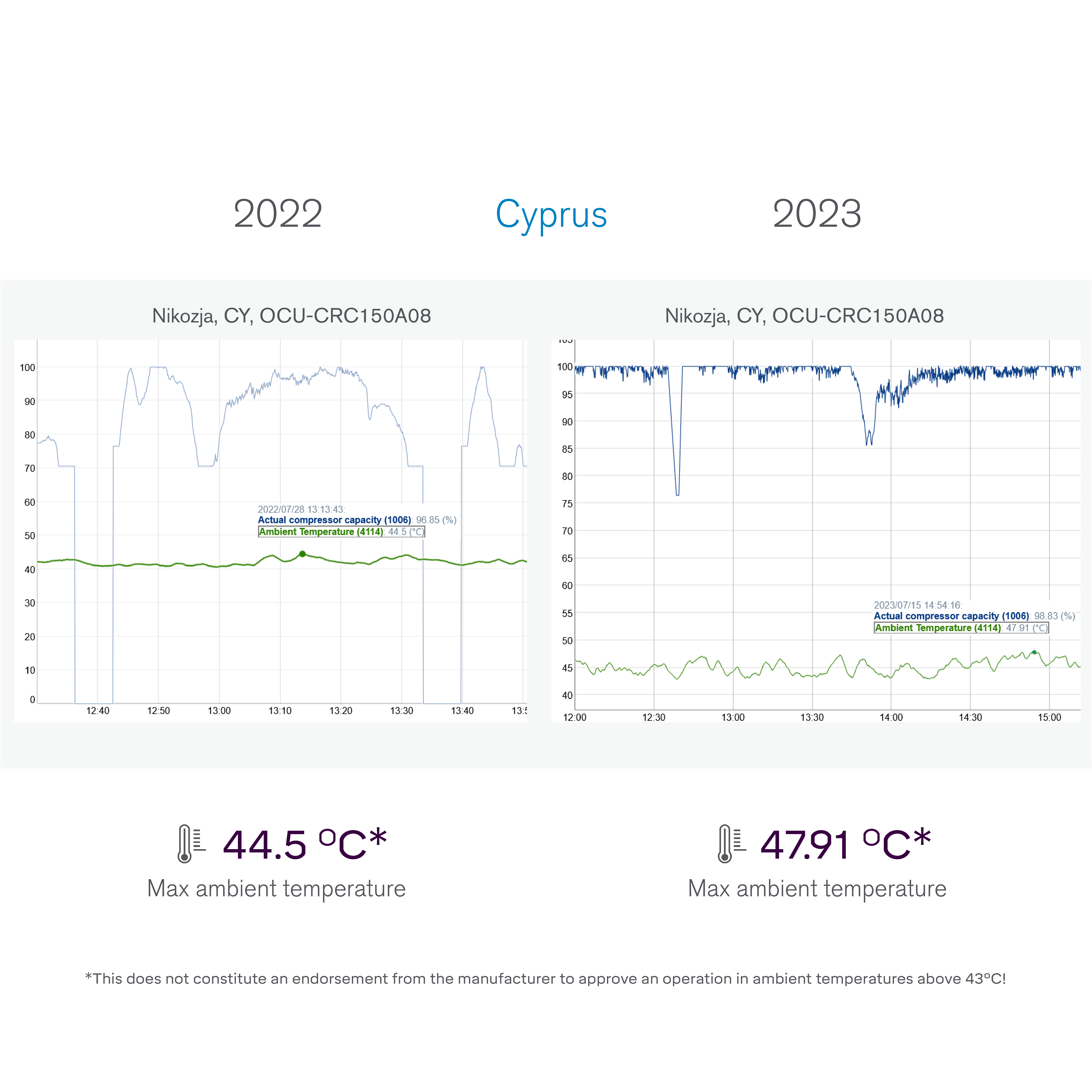

For supermarkets and retail stores, Panasonic offers a portfolio of high-efficiency, high-performance transcritical iCORE CO₂ units. Panasonic has been continuously developing CO₂ refrigeration technology, and today iCORE inverter units are successfully operating in diverse locations worldwide. CO₂ is a proven and reliable technology, and our systems are engineered to maintain outstanding performance even in challenging conditions, with ambient temperatures up to 45 °C*.

Behind this innovation stands our highly qualified production team, continuously advancing their expertise. Beyond manufacturing, we are committed to sharing knowledge with our partners and customers—through expert articles, interactive learning materials, and engaging video animations.