Decentralized Refrigeration Systems: A Scalable Solution for Commercial Applications

przez Panasonic 26-09-2025 Inne

Introduction

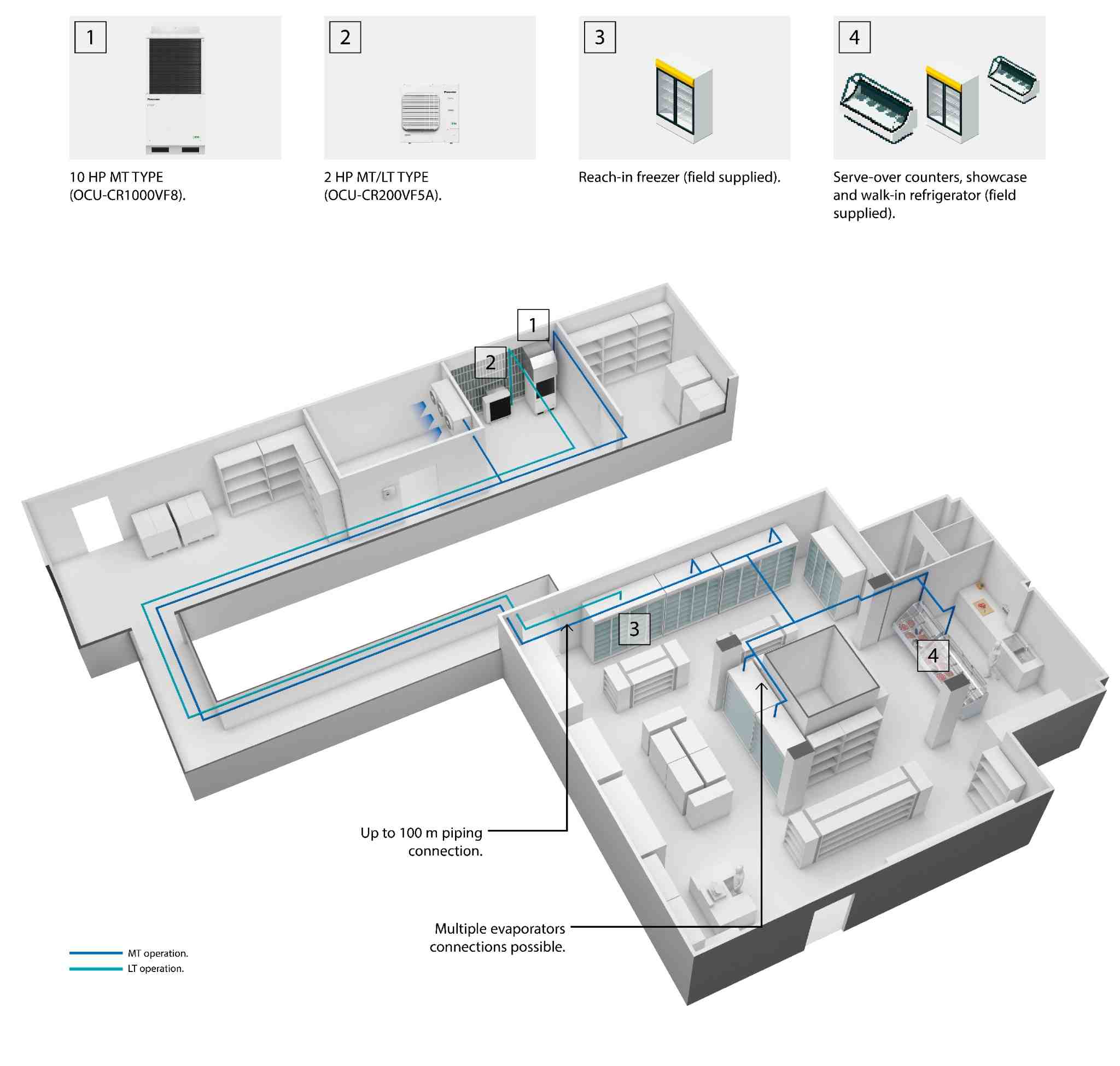

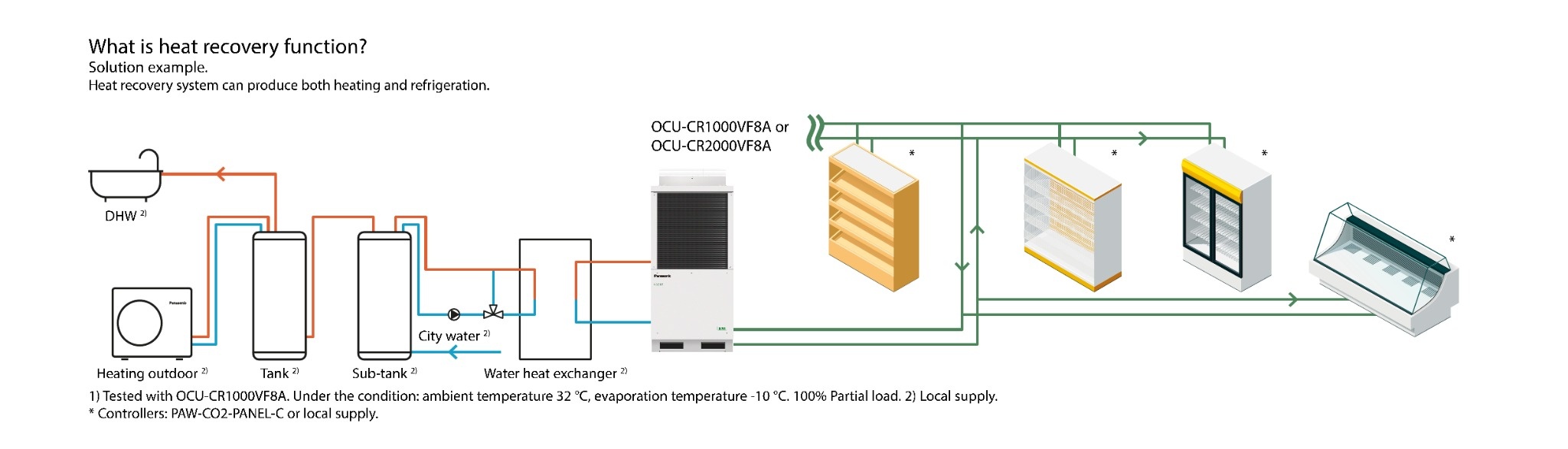

A decentralized system is a commercial refrigeration application concept consisting of several refrigeration units, such as iCORE - transcritical CO2 refrigeration unit - connected to different cooling and freezing devices. These can be chambers or cabinets of different sizes and capacities. An additional part of the decentralized system can be a heat recovery system compatible with total range CO2refrigeration units. Innovative concepts of a decentralized systems are dedicated to commercial refrigeration applications, especially supermarkets of large areas.

The example concept of a complex decentralized solution for a supermarket application is shown and explained in the movie:

https://www.youtube.com/watch?v=AyLCawc5wb4

With a simple user interface, low energy consumption, fast commissioning, and easy maintenance, iCORE by Panasonic is the perfect solution for convenience stores, restaurant cold rooms, fuel stations, and food stores.

Main benefits of the decentralized refrigeration systems

In today’s commercial applications, replacing the powerpack (multi-compressors) systems with decentralized cooling systems results in energy savings, more precise temperature regulation (better product quality), and increased operational safety. The redundancy of the refrigeration units provides the operational safety of the installation. With a decentralized system, that retrofit may be performed step-by-step during the market operation without stopping the business.

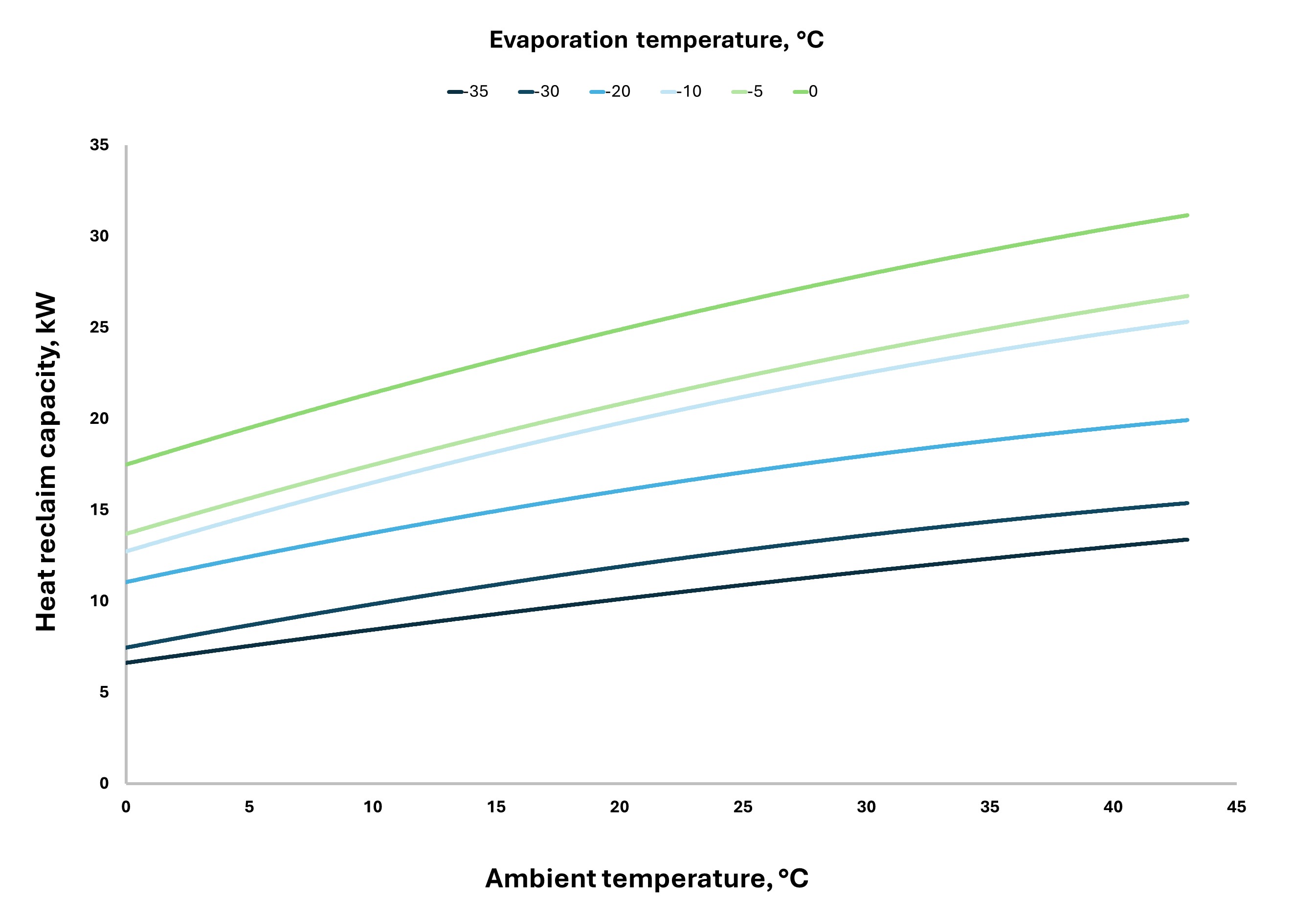

Thanks to the heat recovery option (for selected units), energy costs can be reduced by reclaiming the heat from a high-pressure cooling system for domestic hot water and central heating, for example.

The main benefits of decentralized applications are collected below:

Less cost in operation:

- Higher efficiency thanks to optimized parametrization of the evaporators.

- Smaller refrigerant charge per circuit.

Faster and easier:

- Compact, lightweight Plug&Play unit.

- Smaller diameters and shorter pipelines.

Customized to your needs:

- Easy sales surface extension.

- Modular solution allowing step by step store remodelling.

Higher reliability

- 100% tested with refrigerant in factory.

- Split of cooling systems. No risk of total shut down like in centralized solution

The infographic shows an example of a large retail store after replacing the old power-pack system with a more reliable decentralized solution.

Heat recovery - Smart Energy That Pays Off

Heat recovery systems capture and reuse the thermal energy generated during cooling processes - energy that would otherwise be wasted. By redirecting this heat to support domestic hot water, space heating, or industrial processes, these systems significantly reduce energy costs and carbon emissions. It’s an efficient, sustainable solution that lets you cool and heat at the same time. Investing in heat recovery means investing in smarter, greener energy use.

iCORE transcritical units as the main part of a decentralized system